Did you know that competent complaint handling systems can noticeably promote business growth?

For instance, nearly 70% of customers who voice complaints are inclined to continue with a company if their concerns are resolved and even 95% if the complaints are mitigated immediately, as per the customer service data collected by ABa Quality Monitoring Ltd.

Nearly every company faces unique bottlenecks within its operations, and these challenges can eventually result in missed deadlines, product holds and delays, and disruptions in the supply chain, along with customer complaints, and ultimately lead to a decline in the quality of the business’s product or service.

Product Holds/ Product Release Delays/ Supply Chain Disruptions/ Complaint Resolution = Money on Hold

Recognizing and acknowledging the presence of an issue represents just the first step; the subsequent steps involve identifying its origin and formulating effective remedial processes. This is where conducting a comprehensive root cause analysis (RCA) process plays a critical role.

Understanding the ‘What’ & ‘Why’ of CAPA and Root Cause Analysis

What is CAPA?

CAPA stands for Corrective and Preventive Action. It’s a systematic approach used in various industries to identify, address, and prevent issues, errors, or non-conformities in processes, products, or systems. Corrective actions are taken to fix problems that have already occurred, while preventive actions are implemented to avoid their recurrence in the future. CAPA processes typically involve root cause analysis, corrective action planning, implementation, and monitoring to ensure continuous improvement and compliance with quality standards and regulations.

What is Root Cause Analysis (RCA)?

Root cause analysis strategy refers to a range of problem-solving methods and resources that empower teams to pinpoint the fundamental reasons behind the problems they encounter. However, it extends beyond mere identification of the primary issue and also enables teams to determine the factors that contribute to the problem, devise corrective measures, and elevate business processes by embracing continuous improvement practices.

The main types of root causes fall into three primary categories: systemic (related to processes and organizational factors), human (involving human actions and behaviors), and technical (pertaining to equipment and technology). Some root cause analysis examples are:

-

Food Processing Industry

Problem: Contaminated food products leading to recalls.

Root Causes: Poor sanitation practices, inadequate quality control, supplier issues, and equipment contamination.

Solutions: Implement rigorous sanitation protocols, enhance quality control procedures, vet suppliers more thoroughly, and upgrade equipment.

-

Manufacturing Industry

Problem: Frequent machine breakdowns.

Root Causes: Inadequate maintenance schedules, lack of operator training, poor quality materials, and outdated equipment.

Solutions: Implement a preventive maintenance program, provide training to operators, improve material quality control, and invest in new machinery.

-

Construction Industry

Problem: Structural failures in buildings.

Root Causes: Design flaws, substandard construction materials, lack of inspections, and poor workmanship.

Solutions: Review and improve designs, ensure the use of quality materials, increase inspection frequency, and provide additional training to construction workers.

Significance of Root Cause Analysis

Employing RCA as a strategic tool can lead to safer, more efficient, and sustainable operations for any organization through:

- Strategic Process Enhancement: RCA serves as a critical tool for organizations to identify and address the underlying setbacks within their industrial processes. By delving deep into the core issues, it enables businesses to streamline their processes and align them with their overarching goals.

- Systematic Problem Solving: Identifying the root causes of a problem empowers organizations to develop more proactive approaches for overcoming them, which goes beyond addressing surface-level symptoms, generating more all-encompassing and lasting solutions.

- Prevention of Recurrence: Through RCA and the consequent implementation of appropriate mitigation solutions, employers can significantly or completely prevent the recurrence of similar issues and incidents. This not only safeguards the well-being of workers and the community but also minimizes the risk of damage to the brand’s reputation.

- Cost Reduction: RCA helps organizations avoid unnecessary costs stemming from business interruption, increased regulation, audits, emergency responses, and more. By tackling such issues at their source, companies can save both time and resources.

- Build Public Trust: Prioritizing prevention over mere symptom treatment can earn organizations’ public trust. An incident-free record demonstrates a commitment to safety, which can attract and retain high-performing employees. This, in turn, fosters a culture of safety within the organization.

Principles for an Effective Root Cause Analysis Strategy

The execution of an RCA strategy requires careful planning and adherence to certain principles to guarantee it achieves its intended objectives. Here are some key principles to ensure the RCA strategy in place for a company is working:

Defining Clear Goals: Start by clearly defining the objectives of your RCA strategy.

What specific problems or incidents do you want to address?

What outcomes are you aiming for?

Make sure the objectives are specific, measurable, achievable, relevant, and time-bound (SMART).

Focus on Root Causes, Not Symptoms: RCA should identify and address the root causes of issues, not just the symptoms. Treating symptoms without addressing root causes can lead to recurring problems. Once the root causes are discovered, carrying out appropriate corrective and preventive actions (CAPAs) as part of the RCA strategy is crucial.

Cross-Functional Team: Form a cross-functional team with members from various departments and disciplines. This diversity of perspectives can help uncover a broader range of root causes and potential solutions.

Standardized Process: Develop a standardized RCA process that outlines the steps to be followed, roles and responsibilities, and the tools and techniques to be used. Having a consistent process ensures that all incidents are analyzed in a systematic way.

Use Structured Techniques: Apply structured RCA techniques such as the “5 Whys,” Fishbone (Ishikawa) diagrams, Fault Tree Analysis (FTA), or Failure Modes and Effects Analysis (FMEA) to dig deeper into the root causes.

Review and Validation: Periodically review the effectiveness of implemented solutions to ensure they are addressing the root causes and preventing recurrence.

Essential Guide to Conducting a Root Cause Analysis

Whether enterprises are dealing with a manufacturing defect, a customer complaint, a safety incident, or any other issue, performing an RCA can help dig deep to find the root causes and carry out rectifying actionable.

Rather than a one-size-fits-all solution, RCA must comprise a highly adaptable array of tools, methods, and techniques. Anyhow, the following are the steps on how to perform root cause analysis:

Step 1: Comprehend the Problem

Begin by clearly defining the problem or incident you want to investigate. Ensure that the problem statement is specific, measurable, and well-documented to have a precise understanding of what needs to be analyzed.

Step 2: Gather Information

Collect all available data related to the problem. This may include incident reports, witness statements, photographs, process documentation, and any other relevant information. The more data you have, the better you can understand the issue.

Step 3: Determine Root Causes

Identify the immediate or proximate causes that led to the problem. These are the most visible factors that directly contributed to the incident. Beyond the immediate causes lie the contributing factors, which are often systemic and may have indirectly influenced the problem. Thoroughly investigate and uncover the fundamental reasons behind the problem using suitable RCA techniques or methods.

Step 4: Develop and Employ Corrective and Preventive Actions

Once the root causes are exposed, brainstorm and evaluate applicable corrective and preventive actions. Prioritize the solutions based on their feasibility, impact, and cost-effectiveness, and put the chosen solutions into action.

Step 5: Establish an Organized Plan

Remember to establish a plan for implementing corrective and preventive actions, which should include detailing the necessary resources, designating responsible individuals for task execution, and assessing the potential risks associated with these corrective measures.

Step 6: Monitor and Verify

Continuously monitor the situation to ensure that the problem doesn’t recur. This may include ongoing training, regular audits, or process improvements.

Key Tools for Root Cause Analysis

Several tools and methodologies are employed to conduct RCA in various fields, including manufacturing, healthcare, project management, and quality control, each with its unique advantages and applications. These techniques can be used individually or in combination, depending on the complexity of the problem and the specific goals of the RCA. Let us briefly delve into some mainstream RCA tools:

1. 5 Whys

Reference: https://www.lean.org/lexicon-terms/5-whys/

- The 5 Whys technique is a simple and effective tool for progressively seeking comprehensive answers through a series of probing questions by asking “why” multiple times.

- It involves asking “Why did this problem occur?” repeatedly (usually five times) to uncover the root cause behind each answer.

- The purpose of the 5 Whys is to steer clear of making assumptions. The responses become increasingly precise. Ideally, the final WHY should reveal a flawed process that can subsequently be rectified.

- This activity involves a more thorough exploration of the problem and its underlying causes rather than settling for the initial response, thereby bringing you nearer to the true root of the issue.

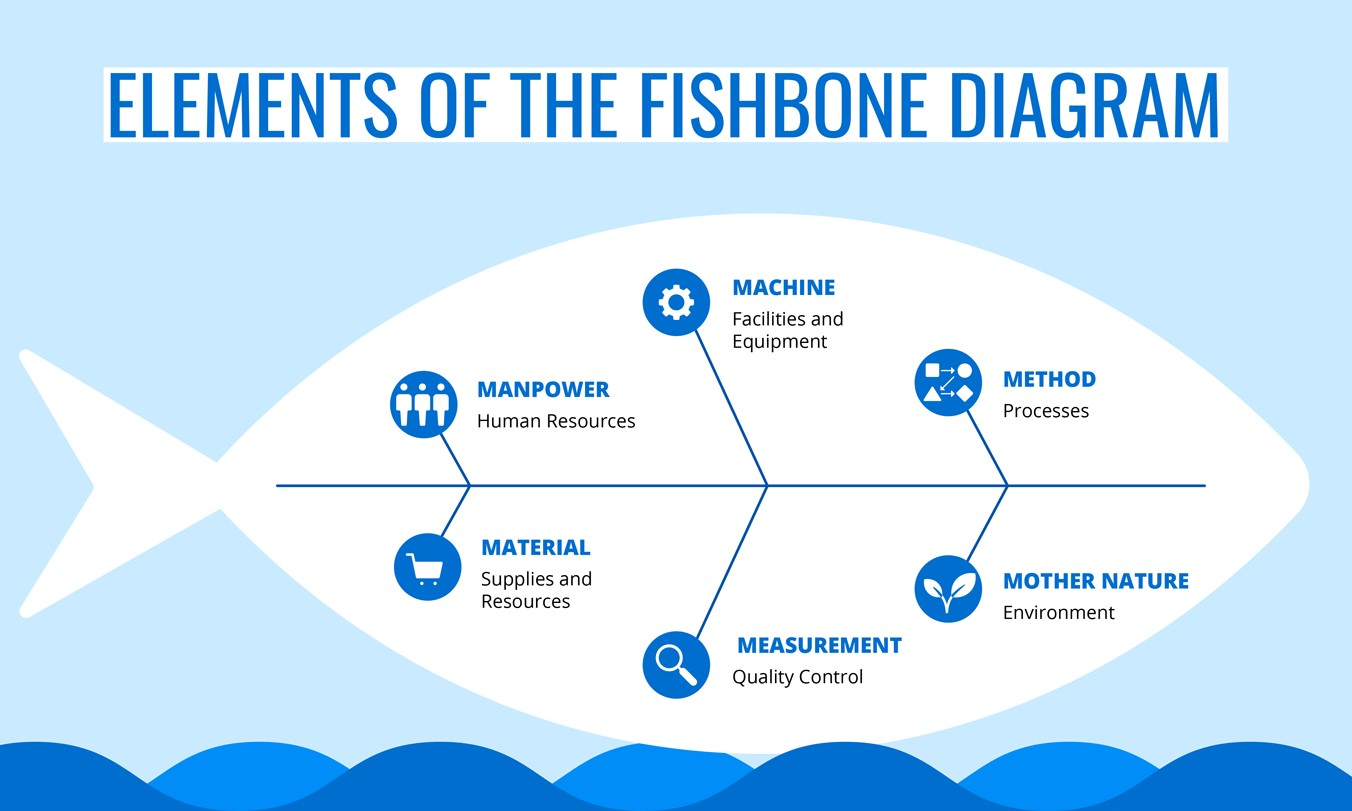

2. Fishbone Diagram (Ishikawa or Cause-and-Effect Diagram)

Reference: https://slidemodel.com/fishbone-diagram-cause-and-effect-analysis/

- A Fishbone Diagram is a visual representation of potential causes of a problem and derives its name from its resemblance to a fish skeleton.

- This diagram features a central line, akin to the backbone of a fish, with spines radiating from both the upper and lower parts of it such that each spine serves as a repository for problem causes. It ultimately converges at the location corresponding to the “head” of the fish, symbolizing the core problem itself.

- It helps teams brainstorm and categorize potential causes into categories like people, processes, equipment, environment, and materials until we arrive at the correct one.

- By structuring the analysis in this way, it encourages an elaborate examination of probable causes.

- It is especially valuable when a problem has multiple contributing factors.

3. FMEA (Failure Modes and Effects Analysis)

Reference: https://freedomsoft.co.in/blog/failure-mode-and-effect-analysis-fmea-in-manufacturing-industry

- FMEA is a structured way of evaluating and attending to the potential failure modes of a product or process and their consequences on the system before an adverse event occurs.

- This method proves valuable in the context of root cause analysis by providing a list of likely failure points warranting investigation. Moreover, it aids in assessing the effectiveness of existing controls in addressing the root causes of issues associated with those failure modes.

- It assigns a risk priority number (RPN) to each potential failure mode based on severity, occurrence, and detectability.

- The goal with mitigation or corrective action is to reduce the overall RPN for each identified risk.

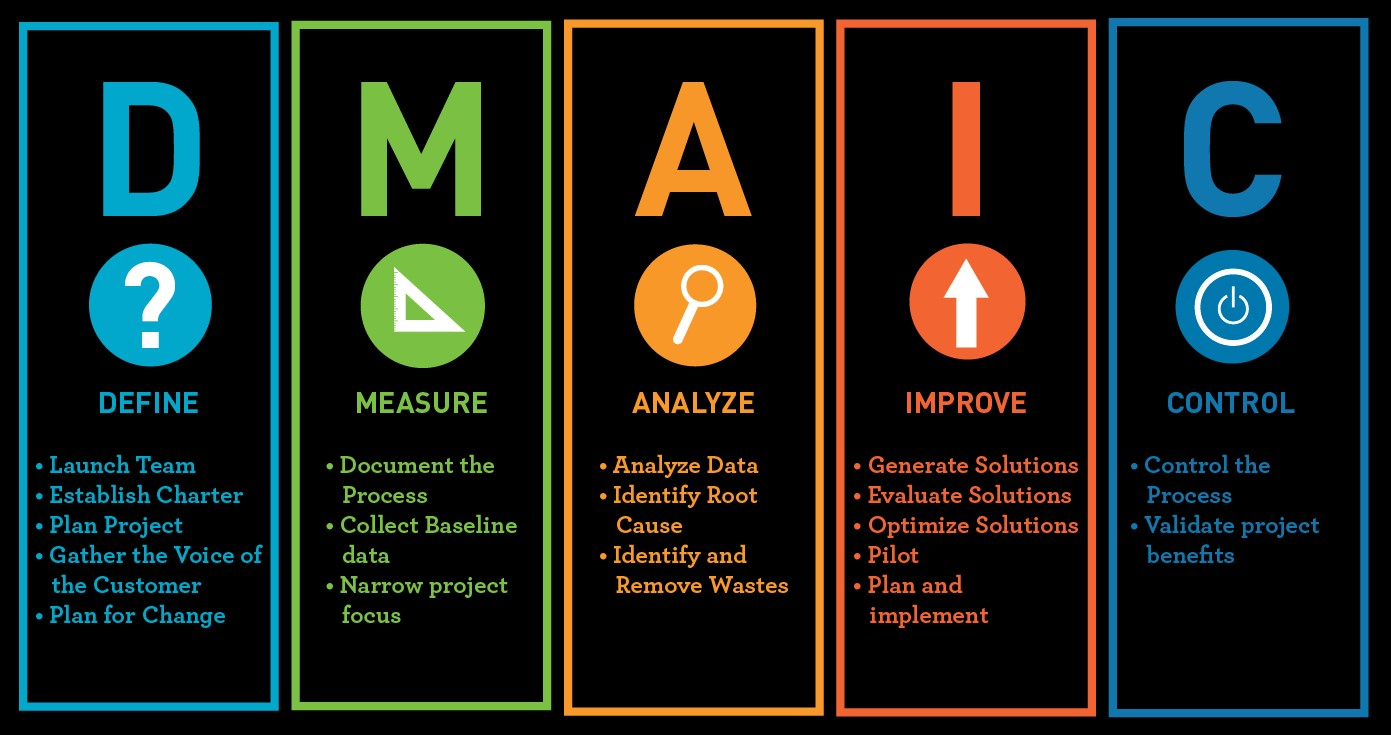

4. DMAIC (Define, Measure, Analyze, Improve, Control)

Reference: https://goproductivity.ca/blog/6187/what-is-dmaic/

DMAIC is a data-driven improvement cycle or framework used in Six Sigma that breaks down problem-solving into the following five steps:

- Define: Define the problem and project goals.

- Measure: Collect data to understand the current process performance.

- Analyze: Analyze the data to identify root causes.

- Improve: Implement solutions to address the root causes.

- Control: Put in place controls to sustain improvements.

5. Pareto Analysis

Reference: https://www.salesforce.com/ca/blog/2016/09/80-20-rule.html

- Pareto Analysis is based on the Pareto Principle, which is premised on the idea that 80% of a project's benefit can be achieved by doing 20% of the work—or, conversely, 80% of problems can be traced to 20% of the causes.

- It is a powerful quality and decision-making tool to yield the necessary facts needed for setting priorities, and by focusing efforts on the vital few causes, it helps allocate resources efficiently for problem-solving.

6. FTA (Fault Tree Analysis)

- FTA is a deductive analysis method used to determine the root causes of a specific event by working backward from the event.

- An FTA uses boolean logic to determine the root causes of an undesirable incident.

- It uses graphical representations of fault trees to analyze various events and their relationships.

- At the top of the fault tree, the undesirable result is listed. From this event, all potential causes tree down from it.

Smart CAPA as a Tech-Enabled Solution to Optimize RCA Processes

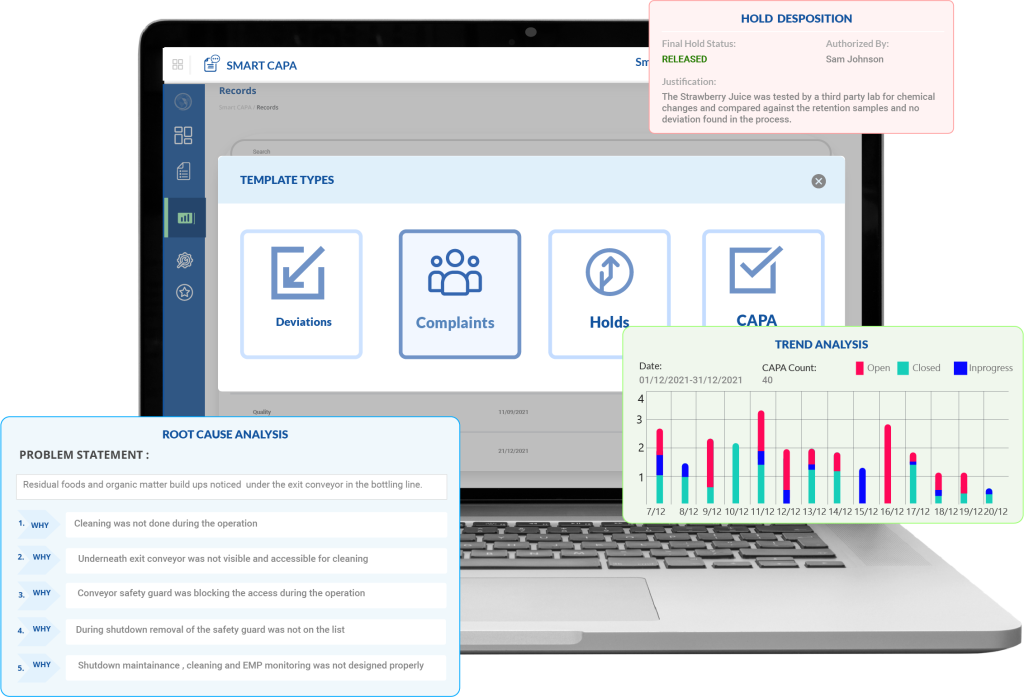

Smart CAPA is a game-changing digital solution engineered to enhance the speed and efficiency of leveraging corrective and preventive actions (CAPA) by providing seamless access to CAPA information, facilitating in-depth data analysis for pinpointing root causes, fostering collaboration among team members, offering real-time visibility into CAPA progress and empowering responsible individuals with insights to prevent future incidents.

Complaints, Holds, & Deviations Management

Smart CAPA streamlines the entire complaint lifecycle, from investigation to resolution. Digitizing CAPA processes empowers organizations to reduce product holds and deviations, driving continuous improvement.

Configurable Templates

Create customized templates for complaints, deviations, holds, and CAPA, or tailor pre-built templates to match your specific data requirements. Users can effortlessly select the information they need for their records.

Record Creation

Smart CAPA simplifies the generation of comprehensive, auditable records using configured templates. This centralizes the management of extensive CAPA records for easy tracking and retrieval.

Investigation Management

Conduct structured and thorough investigations by digitally gathering relevant data and documentary evidence. This aids in identifying the underlying factors contributing to quality or compliance issues.

Root Cause Analysis

Utilize integrated systematic Root Cause Analysis (RCA) models, such as the 5 Whys or FishBone Analysis, to determine the causes of issues and develop targeted corrective and preventive action plans.

Non-Compliance Management

Plan, define, and implement non-compliance action items efficiently. Assign corrective and preventive actions to respective employees for prompt rectification, compliance maintenance, and future risk mitigation.

Verification of Effectiveness & Closure

Evaluate and validate the effectiveness of corrective and preventive actions. Ensure the successful closure of the CAPA process by reviewing and confirming the resolution of nonconformances.

Reporting & Trend Analysis

Smart CAPA empowers you to generate customized reports and analyze data trends. Detect, correct, and review outliers in your processes, gaining invaluable insights for informed decision-making and continuous improvement.

Say goodbye to manual, time-consuming tasks and embrace a streamlined approach to CAPA management and root cause analysis processes with Smart CAPA to drive compliance and excellence across your enterprise.