Every manufacturing industry operates under a strict lens of quality and safety, where even minor deviations can have far-reaching consequences. Among these challenges, Out-of-Trend (OOT) incidents often emerge as silent disruptors. These incidents, which occur when data trends deviate from expected baselines, can signal potential quality or safety risks. While they may not always breach established specifications, OOT incidents demand careful attention to ensure they do not escalate into serious compliance or operational issues.

Here, we will explore the concept of OOT incidents, their causes, the critical need for proactive prevention, and how a modern solution like Smart CAPA can empower food businesses to deal with OOT events the right way.

What Are Out-of-Trend (OOT) Incidents?

OOT incidents refer to deviations in data trends that fall outside of the expected or historical norms. Unlike Out-of-Specification (OOS) results, which indicate immediate non-compliance with predefined criteria, OOT incidents reflect potential early warnings of issues that could worsen over time. This makes identifying and mitigating OOT incidents a vital part of quality management in the food industry.

Examples of OOT incidents in the food industry include:

- A gradual increase in microbial counts during routine environmental monitoring.

- Slight but consistent shifts in product pH levels that deviate from historical patterns.

- Unusual variations in packaging seal strength across multiple production batches.

While these trends may initially seem insignificant, they can escalate into major non-conformities if left unchecked, leading to product recalls, regulatory scrutiny, and damaged consumer trust.

How Do OOT Incidents Occur?

Understanding the root causes of OOT incidents is the first step toward mitigating them effectively. These incidents can stem from various factors, including:

- Process Variability: Even minor fluctuations in manufacturing processes can accumulate over time, resulting in data trends that diverge from established norms. This variability often stems from unoptimized processes or inconsistent control measures.

- Equipment Degradation: Machinery and equipment wear out over time, leading to subtle changes in performance. For example, a filling machine might gradually deliver inconsistent volumes, leading to OOT trends in packaging weights.

- Environmental Factors: Seasonal changes or uncontrolled environmental conditions can affect raw materials and production outcomes. For instance, changes in humidity may impact the moisture content of products.

- Human Error: Inconsistent operational practices or unintentional errors during production or quality control can introduce variability, creating OOT trends that require investigation.

- Raw Material Variations: Natural inconsistencies in raw materials, such as ingredient quality or supplier variations, can contribute to OOT incidents in finished products.

Why Having a Hold on OOT Incidents Is Essential

The consequences of ignoring OOT incidents can be far-reaching and costly. Here are some critical reasons why proactive prevention is non-negotiable:

Preventing Product Recalls

OOT incidents, if unaddressed, can escalate into full-blown Out-of-Specification (OOS) failures. For example, a gradual microbial count increase may go unnoticed until it breaches safety limits, triggering a product recall. Recalls not only incur significant financial losses but also erode consumer trust.

Ensuring Regulatory Compliance

Regulatory authorities, such as the FDA or local food safety bodies, place a strong emphasis on trend analysis and quality management. Failure to address OOT incidents can lead to increased scrutiny, penalties, or suspension of operations.

Maintaining Brand Reputation

In today’s competitive market, brand reputation is invaluable. OOT incidents that lead to product defects or safety concerns can quickly tarnish a company’s image, resulting in long-term damage to customer loyalty and market position.

Driving Continuous Improvement

Proactively addressing OOT trends allows businesses to identify inefficiencies, optimize processes, and enhance product quality. This not only ensures compliance but also fosters a culture of continuous improvement, which is critical for long-term success.

Capture and Manage OOT Incidents Like a Pro with Smart CAPA

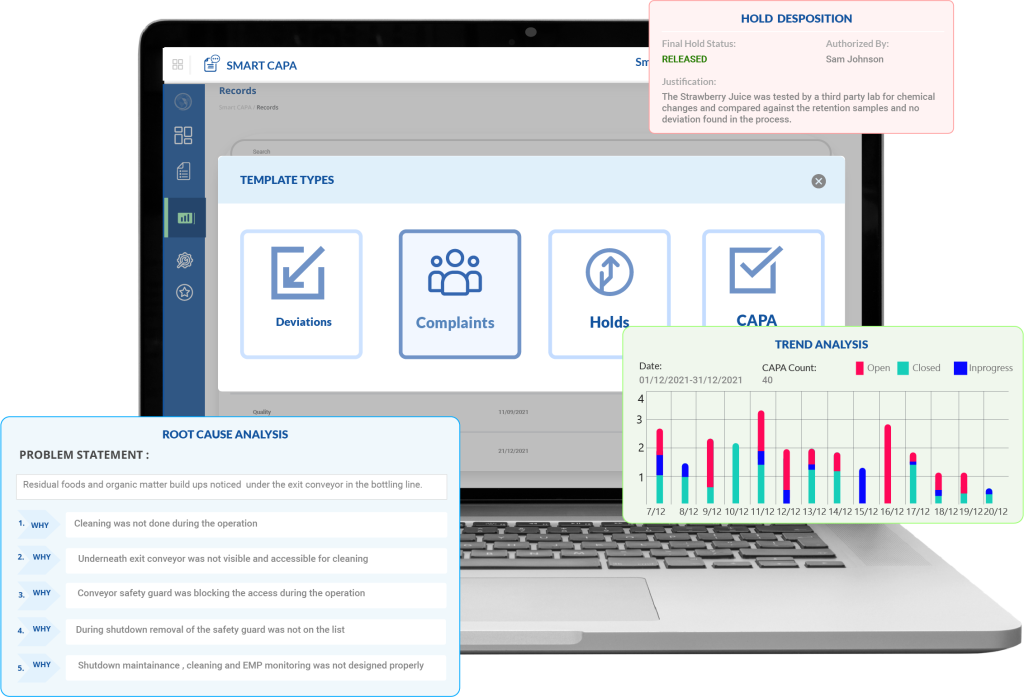

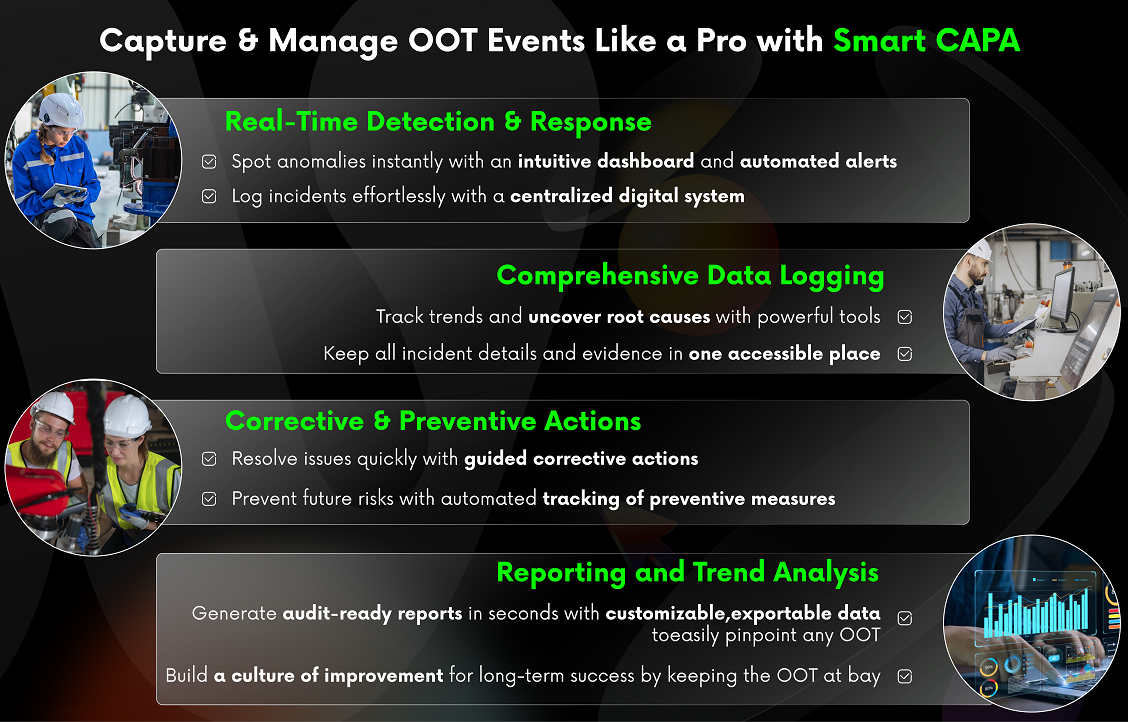

In a landscape where even minor deviations can have significant consequences, businesses need a proactive solution to manage Out-of-Trend (OOT) incidents effectively. Smart CAPA is a digital platform designed to streamline corrective and preventive actions (CAPA), enabling businesses to identify, address, and resolve issues with precision. Here’s how Smart CAPA empowers food businesses to stay ahead of OOT incidents:

1. Real-Time Detection & Response

Smart CAPA integrates real-time monitoring to instantly detect deviations from established trends:

- Interactive Dashboards: Visualize trends in real-time with intuitive, color-coded alerts that immediately highlight OOT incidents.

- Automated Alerts: Get instant notifications when deviations occur, enabling your team to act swiftly before issues escalate.

- Digital Incident Logging: Log OOT incidents with detailed information—such as date, description, root cause, and evidence—using easy-to-fill forms, creating a centralized digital record for each event.

2. Simple Data Logging for Root Cause Analysis

Once an OOT incident is flagged, Smart CAPA simplifies the analysis and resolution process:

- Incident Details & Evidence: Document every aspect of the incident, including the nature of the deviation, affected processes/products, and relevant supporting evidence like photos or test results.

3. Streamlined Corrective & Preventive Actions

Smart CAPA guides your team through the CAPA process, from identification to resolution:

- Corrective Actions: Based on the root cause, the platform automatically suggests corrective actions and tracks their implementation, ensuring that each step is documented and completed within a defined timeline.

- Preventive Actions: Beyond just fixing issues, Smart CAPA helps develop preventive actions to reduce the recurrence of OOT incidents by making actionable insights available to minimize risks.

- Follow-Up Tracking: Monitor corrective actions through follow-up tracking to verify their effectiveness in eliminating or controlling the issue.

4. Reporting & Trend Analysis

After corrective actions are implemented, Smart CAPA ensures that improvements are sustained by generating reports and executing trend analysis:

- Predefined Reports: Access ready-made reports that track the status of CAPA actions, trends in OOT incidents, and effectiveness of preventive measures.

- Customizable Reporting: Tailor reports to suit your needs by filtering data based on parameters like product, process, or time, allowing for deeper analysis and more focused audits.

- Trend Analysis: Utilize powerful graphical tools to track deviations over time, pinpoint recurring patterns, and identify the root causes, enabling you to address issues at their source. This helps uncover systemic problems and allows for proactive improvements.

Out-of-trend (OOT) incidents are a reality in the food industry, but they don’t have to be a source of risk or uncertainty. Don’t let OOT incidents compromise your product quality or reputation. Take control with Smart CAPA and ensure that your operations remain resilient, compliant, and optimized for success.